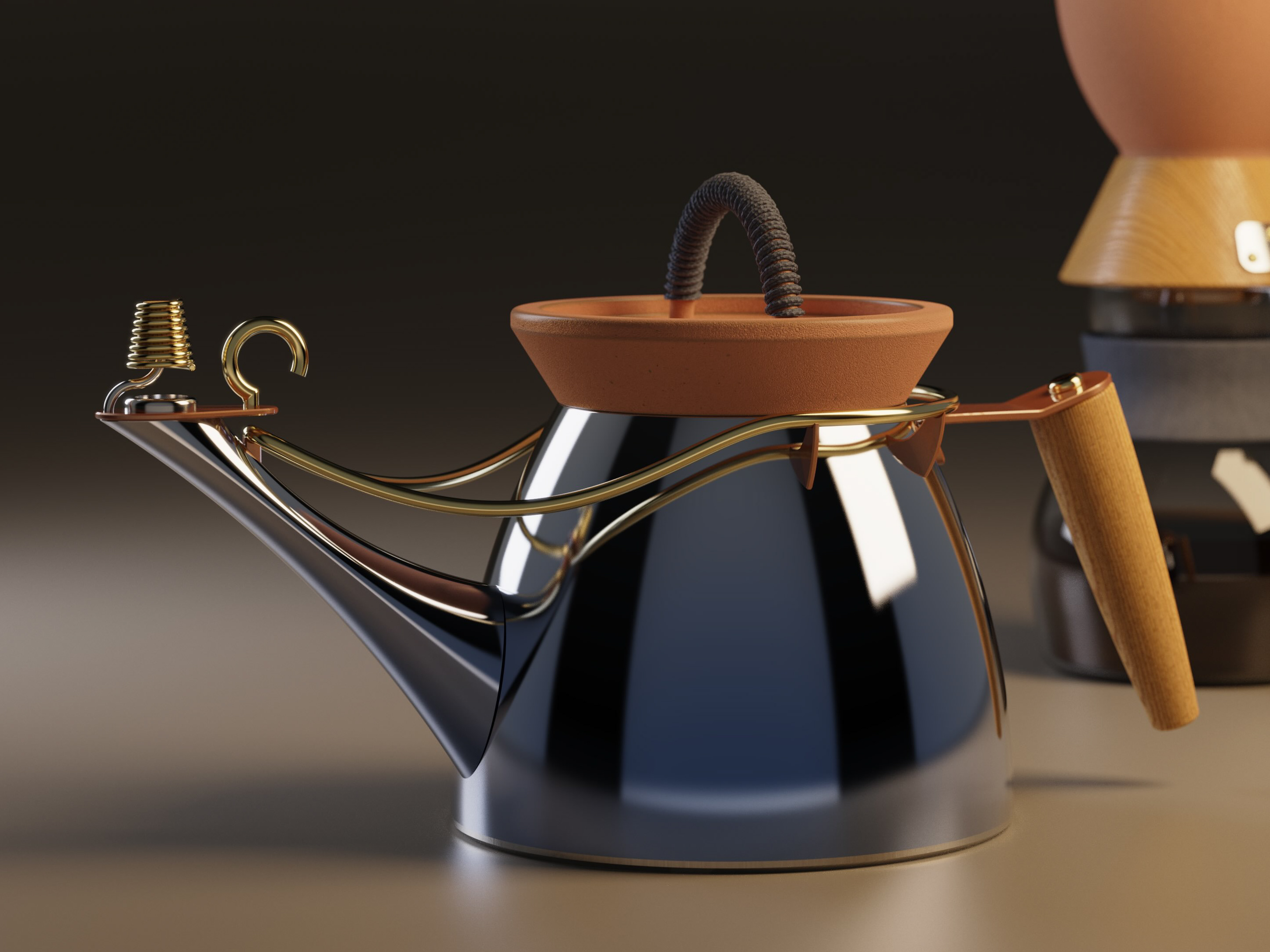

DT-309A Torch

There is no space in the current torch to increase the size of the battery. The case and carabiner need to be redesigned to allow for this and a more ergonomic winding handle.

Cross-sectional area must be kept the same to avoid compromising ergonomics & one-handed operation.

The materials used in the current torch are functional but, together with the design, feel cheap and generic.

Re-designing the outer shell to be compatible with a textured mould would produce a superior surface finish and alleviate the need for external ribs.

A comprehensive LCA shows...

Battery capacity has been increased by 350%

This dramatically improves runtime, with battery cost only increasing from 24p to 78p (500 units).

This dramatically improves runtime, with battery cost only increasing from 24p to 78p (500 units).

Significant increase in product lifespan

Fewer charge cycles experienced by the battery per lumen-hour.

Fewer charge cycles experienced by the battery per lumen-hour.

ABS usage increases by 5.3g (15.7%)

To manufacture longer case and improved winding handle.

To manufacture longer case and improved winding handle.

Only 14% increase in CO2 footprint and total energy usage

Estimated. Due to increase in ABS and battery capacity, with some offset by removal of solar panel.

Estimated. Due to increase in ABS and battery capacity, with some offset by removal of solar panel.

34% increase product cost

Estimated. From £1.44 to 1.93 (500 units).

Estimated. From £1.44 to 1.93 (500 units).