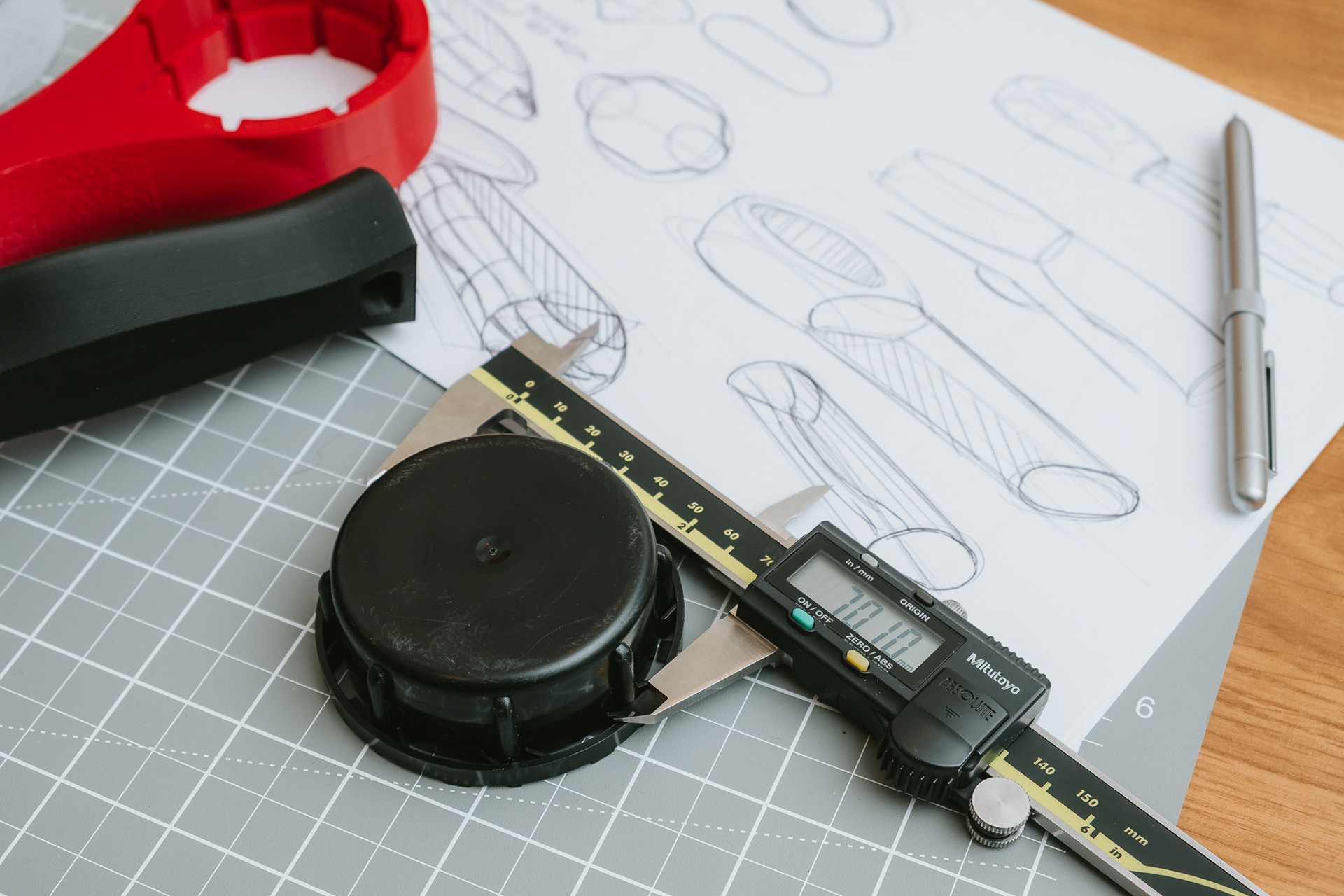

Optimised for Additive & Mass Manufacturing

Full 50-page technical report available to read on request.

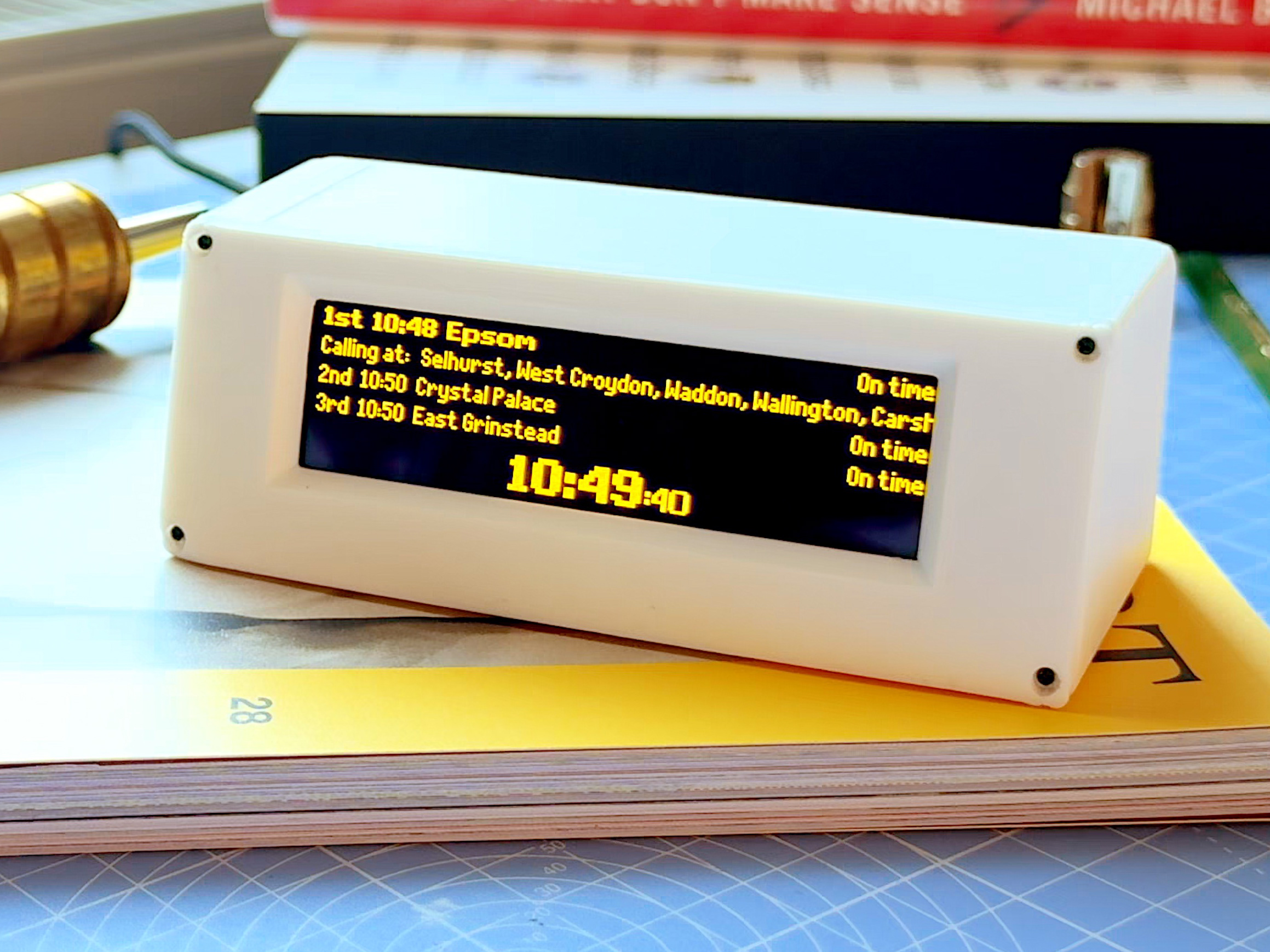

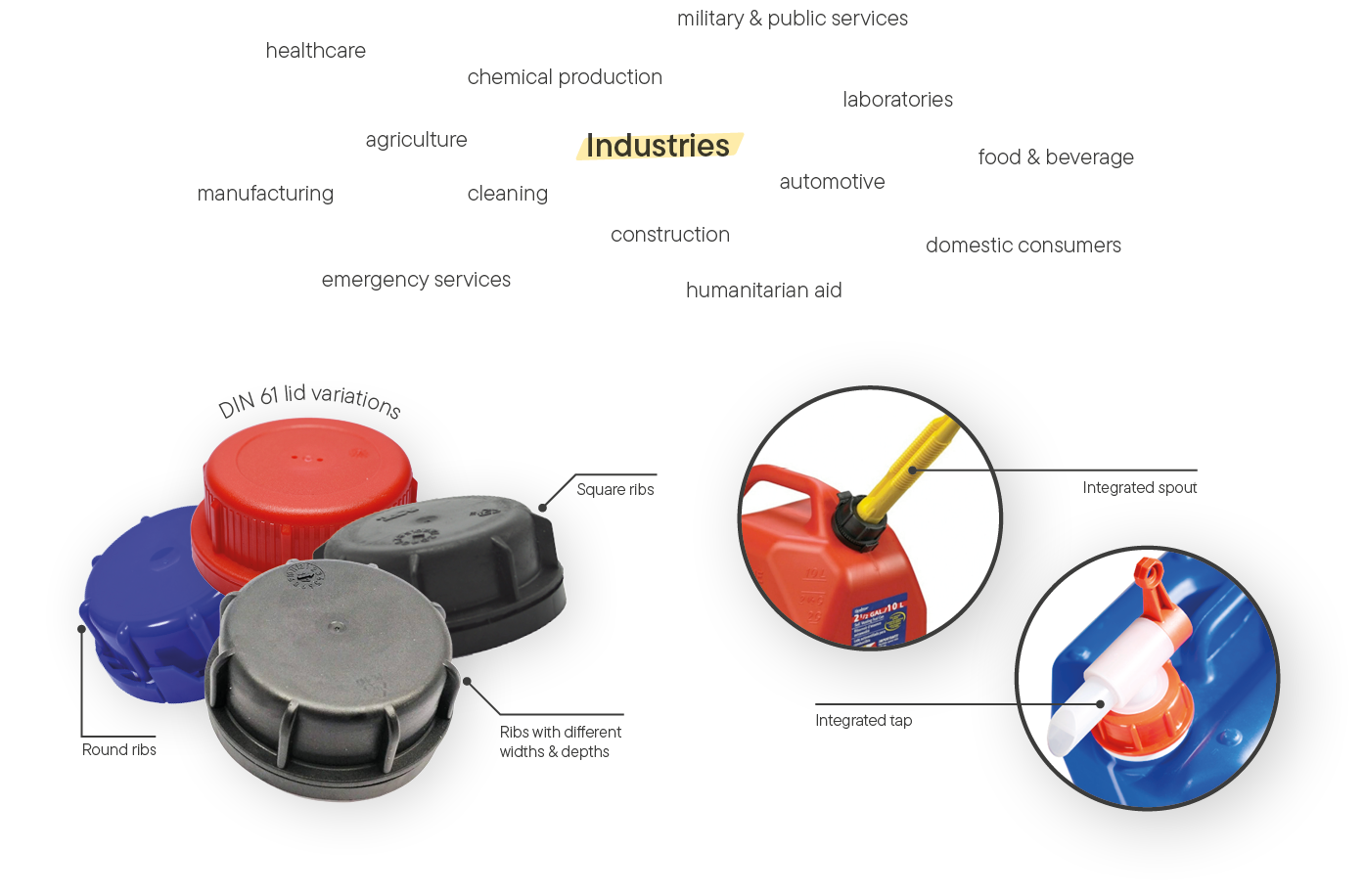

DIN 51 & 61 HDPE Jerry Cans

A ubiquitous design...

Thread geometry is standardised by DIN, but lid and jerry can design are not.

Max opening & closing torque = 25 Nm

Equates to 714N → over 70 kg without assistance

Over 10 million adults, young people and children in the UK live with arthritis.

It is the single biggest cause of physical disability.

It is the single biggest cause of physical disability.

Arthritis UK, 2025

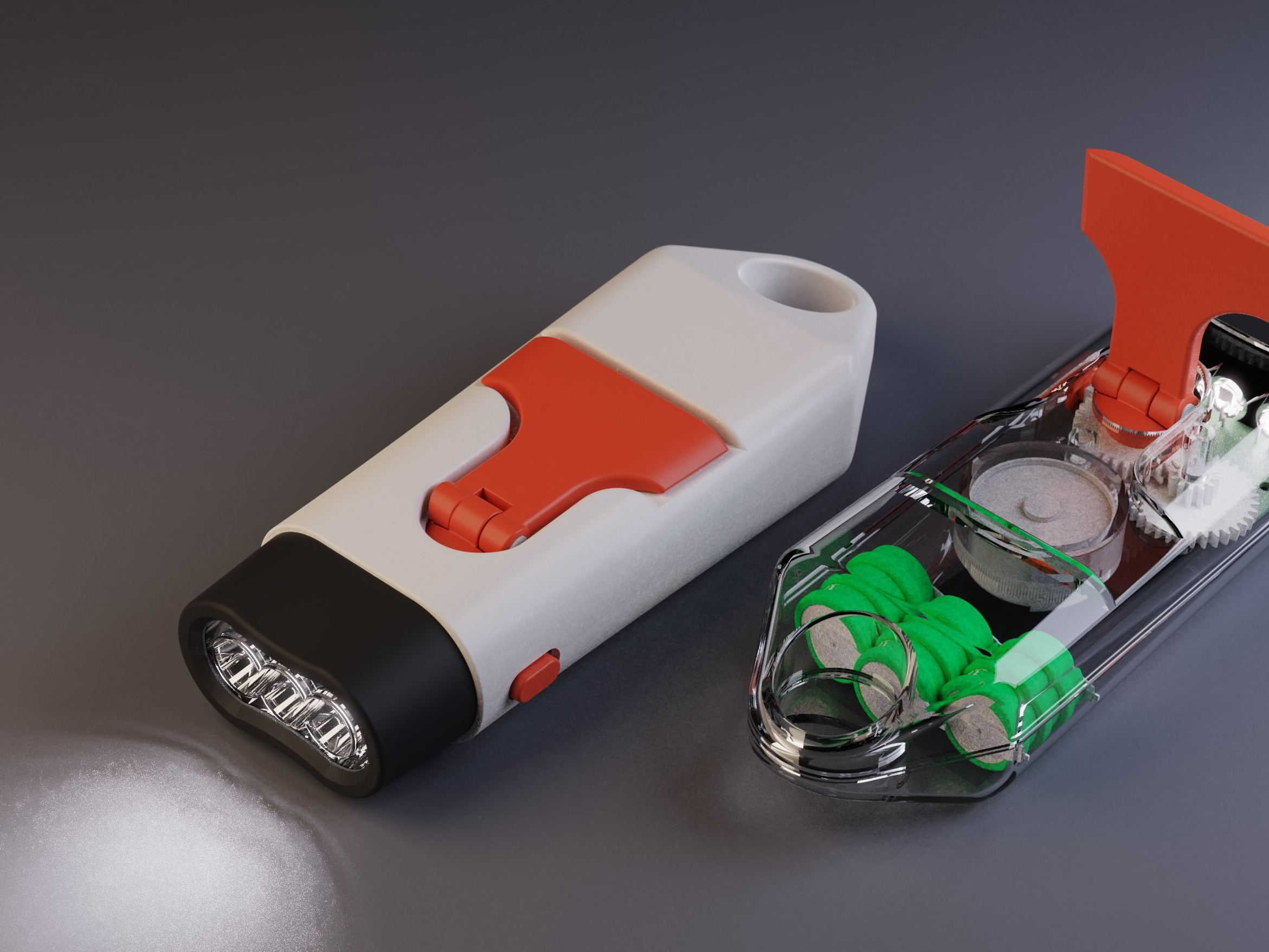

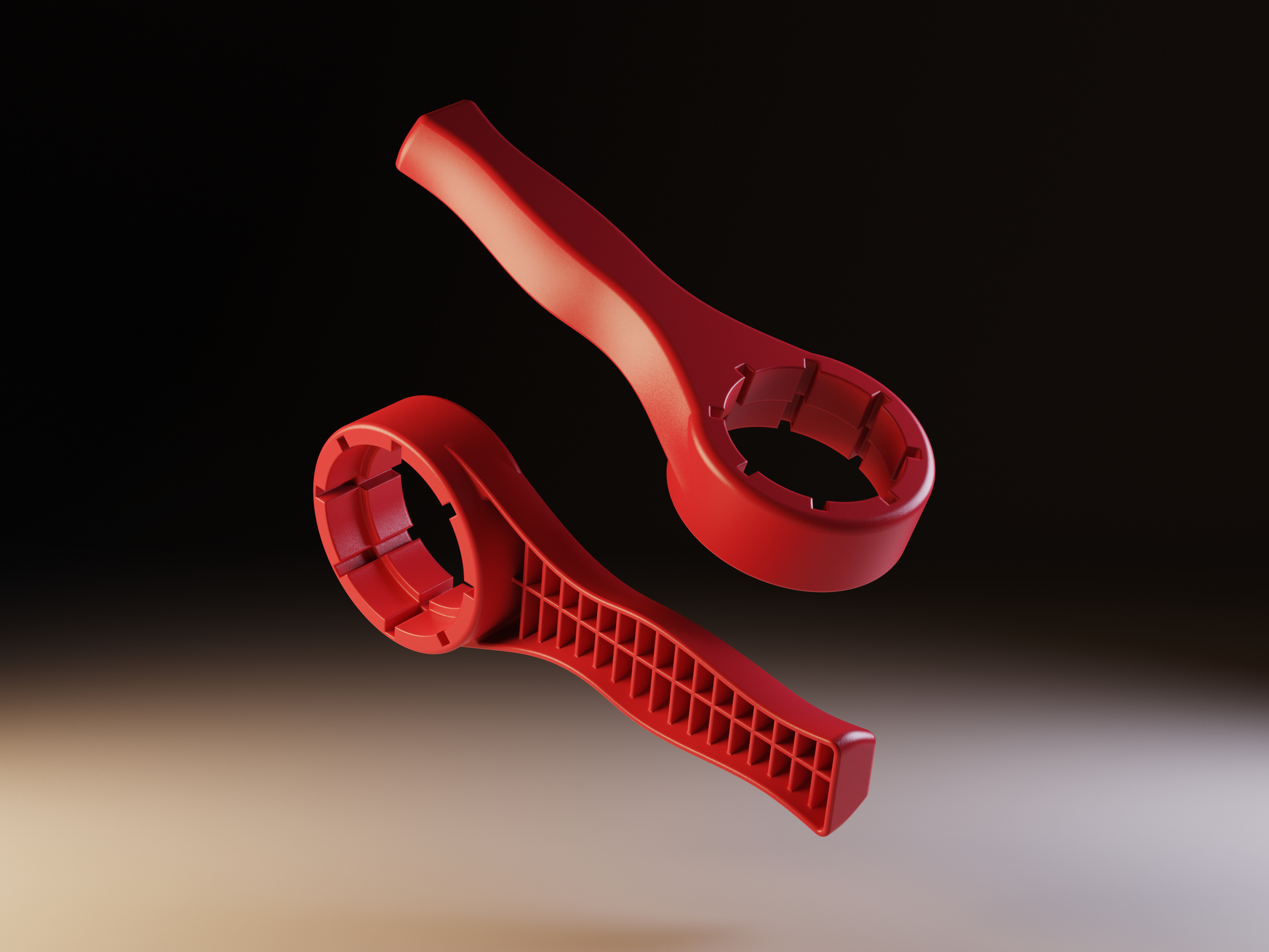

Brief

Design a product that aids in opening and closing a plastic jerry can. Key drivers are improving users' grip on the lid, their ability to apply torque, and making the whole action 'easy'.

Must be viable for 3D printing and adaptable to injection moulding.

Problem Statement

People with osteoarthritis struggle to open most screw-top designs, including the jerry can. How can an assistive aid can be produced that reduces this friction to the point that it does not interrupt daily life.

The solution should benefit anyone, not just those with osteoarthritis.

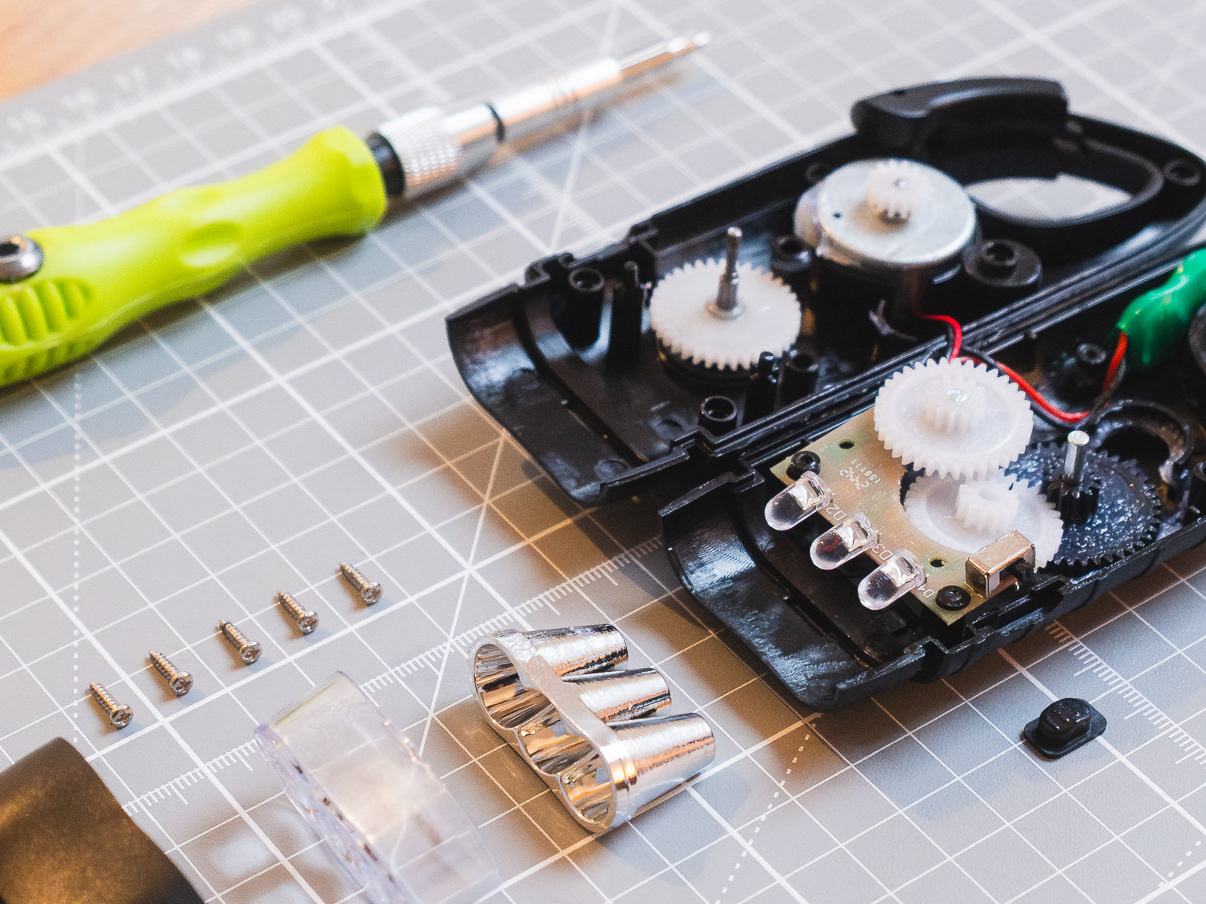

3D Printing

Injection Moulding

“small, but meaningful, improvements”

This project continues the conversation around inclusive handle design in everyday life.

3D printing can facilitate it for both new products and retrofit → democratising good design.

Download for free on Printables and try it for yourself!